A HIAB (or lorry-mounted crane) is one of the most valuable pieces of equipment on any construction, transport, or logistics job. To keep it running smoothly—and to keep operators safe—regular maintenance is essential. Whether you use your HIAB daily or only on certain projects, a good maintenance routine helps prevent breakdowns, reduces repair costs, and ensures compliance with safety regulations.

Below is a practical, easy-to-follow guide on how to look after your HIAB all year round.

1. Start With Daily Pre-Use Checks

Before operating the crane, a quick visual inspection can prevent serious issues later. Operators should check for:

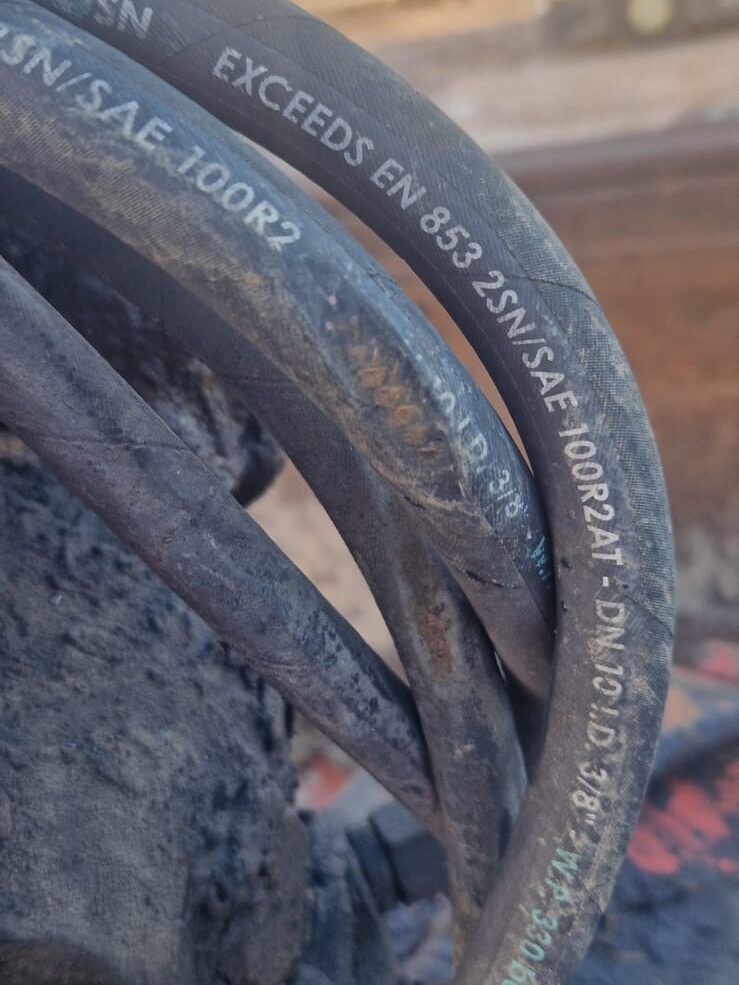

✔ Hydraulic leaks – Inspect hoses, joints, and cylinders for drips or signs of wear.

✔ Loose bolts & fixings – Vibration can cause components to loosen over time.

✔ Damaged or frayed hoses – Hydraulic hoses are under constant pressure—small wear can quickly become a major leak.

✔ Boom condition – Look for bends, cracks, rust patches, or anything out of the ordinary.

✔ Oil levels – Low hydraulic oil is one of the most common causes of HIAB issues.

2. Keep the HIAB Clean

Dirt, grit, and salt (especially in winter) can cause premature corrosion. Keep the crane components clean, paying special attention to:

- Hydraulic rams

- Boom sections

- Stabiliser legs

- Electrical connectors

A regular pressure wash—excluding sensitive areas like electrical junction boxes—helps extend its lifespan.

3. Lubrication: The Key to Smooth Operation

Lubrication is one of the most important maintenance tasks.

Grease points to check regularly:

- Boom extension sections

- Slewing mechanism

- Stabiliser hinges

- Knuckle joints

- Chain/cable areas (if applicable)

Follow manufacturer instructions regarding grease type and frequency. Over-greasing can be just as harmful as under-greasing, so stick to the recommended schedule.

4. Hydraulic System Health

The hydraulic system is the heart of your HIAB. Keep it healthy by:

● Checking hydraulic oil quality

Oil should be clean and free from milkiness (a sign of water contamination) or metal particles.

● Replacing oil & filters regularly

Contaminated oil causes system failures.

● Inspecting hoses & seals

Replace anything suspect before it becomes a failure point.

5. Stabiliser Leg Maintenance

Stabilisers are essential for safe lifting. Make sure they:

- Extend and retract smoothly

- Have no rust, bends, or structural damage

- Are greased correctly

- Have functioning safety switches

- Have clean footplates with no cracks

Poor stabiliser maintenance is one of the biggest causes of accidents involving lorry loaders.

6. Electrical System Checks

Modern HIABs rely heavily on electronics.

Check regularly that:

- Remote controls connect properly and have no visible damage

- Warning lights and indicators function

- Sensors are clean and correctly aligned

- Wiring is not frayed, pinched, or exposed

7. Scheduled Professional Servicing

Daily checks are essential, but professional servicing is equally crucial.

A competent person should perform:

- LOLER thorough examinations (usually every 6 or 12 months)

- Annual pump and valve inspections

- Structural integrity checks

- Load testing

- Software updates for modern HIAB systems

Skipping professional servicing risks fines, downtime, and unsafe lifting conditions.

8. Operator Training & Safe Use

A HIAB is only as safe as the person operating it.

Ensure operators are:

- HIAB-certified or CPCS trained

- Regularly refreshed on safe lifting procedures

- Familiar with load charts and safe working loads

- Trained to recognise early signs of faults

Poor technique leads to unnecessary strain and faster wear on components.

9. Keep Records of All Maintenance

A simple logbook or digital system should track:

- Pre-use checks

- Repairs

- Fault reports

- LOLER inspections

- Service dates

- Hydraulic oil/filter changes

Accurate records keep your fleet compliant and make future maintenance more efficient.

Conclusion

General HIAB maintenance doesn’t need to be complicated. With daily checks, good lubrication, regular cleaning, and scheduled professional services, you can keep your lorry loader running safely and efficiently all year round.

A well-maintained HIAB not only lasts longer but also keeps your team safe and your business compliant.

If you spot any defects or require a service, please get in touch!

Call 01246 607222

Email – service@moosecraneandplant.com